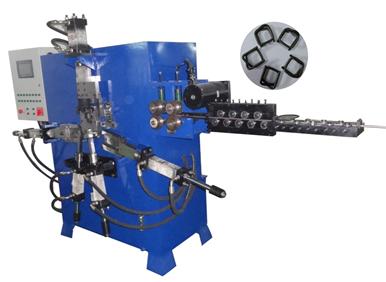

Hydraulic drive Machine for making strapping buckle

Hydraulic drive Machine for making strapping buckle

Hydraulic strapping buckle machine

If you need one machine to produce all the sizes of the buckles and do not care about

the speed and production rate of the machine, so the hydraulic drive system is one of

your selections which enable you to make 13 16 19 25 and 32 mm buckles in one

machne by changing the molds each other.

Video of the 32 mm x 7 mm buckle machine:

1.Model and Specification

|

Model |

ST-B5 |

ST-B7 |

St-B8 |

|

Wire size(dia) |

3.0-4.0mm |

3.0-7.0mm |

5-8mm |

|

Buckle size |

13/16/19/25mm |

13/16/19/25/32mm |

25mm*5.0 32mm*7.0 40mm*8.0 |

|

Feeding length |

400mm |

400mm |

400mm |

|

Production rate |

18pcs/minute |

12pcs/minute |

10pcs/minute |

|

Motor power |

5.5kw |

5.5kw |

5.5KW |

|

Size(L*W*H)mm |

1800X900X1930 |

1890x900x1980 |

1800X900X1930 |

|

Weight |

1300.0KG |

1500.0KG |

1600.0KG |

2. Coil stand is attached in the machine

3. Each machine has only one size of mold installed in the machine

If extra new size mold is needed there will be extra charge for new mold which cost is 500 USD/set.

4 the machine is packed by plywood for exportation

5. If you need light machine for 13 16 and 19 you may chose ST-B5 with higher speed and if you

need heavy duty machine for size up to 32 mm you may chose model ST-B7 or St-B8 for super

heavy duty of 40mm*8.0

6. Delivery 45 days after down pay ( balance payment against confirmation of samples and testing

video from the new machine sent to customers)

7. Feature of the machine

The machine is designed and driven by hydraulic system with PLC

which can produce wire buckle with hard steel wires

It is lower cost than CNC machine with same production capacity and stable quality better than

the one by pneumatic system It save the labor and one worker can look after three machines in the same working day as it is PLC controlled

8 video for testing of the machine