semi automatic steel strap clip machine with numbers controlling counter

|

CATALOGUE FOR SEMI AUTO STEE STRP SEAL MACHINE |

|

|||||||||||

|

Specification for Seal Machine |

|

|||||||||||

|

Machine Name |

Seal machine |

CE CERTIFICATION NO.: |

M.2019.206.C2559 |

|

||||||||

|

Model No. |

P-1932 (SUBORDINATE MODEL OF FR-3) |

CE REPORT NO: |

TCF no. MICEZ-1903-0265-MD+LVD |

|

||||||||

|

|

CE COVER PAGE |

|

|

|||||||||

|

Technical data |

seal size |

|

||||||||||

|

Seal |

W |

L |

T |

|

|

|||||||

|

Technical data |

32 mm (inner diameter size)) |

32 mm |

45-57 mm |

0.7-1.0 |

|

|||||||

|

19 |

19 |

45-57 mm |

0.7-1.0 |

|

||||||||

|

Feeding L |

260-400 mm |

|||||||||||

|

Production rate |

60-PC/MINUTE |

|||||||||||

|

Motor power |

1 kw |

|||||||||||

|

Voltage plans |

V |

Phase |

HZ |

|||||||||

|

A plan |

380 |

3 |

60 |

|||||||||

|

B plan |

220 |

3 |

60 |

|||||||||

|

Technical data |

C plan |

220 |

Single phase |

|||||||||

|

Accessories |

|

|

||||||||||

|

Automatic control counter for numbers controllong |

|

|||||||||||

|

Cutter of Spring Steel: 3 pieces |

|

|||||||||||

|

Core-plates parts 2 pieces. for each size o f32 and 19 mm |

||||||||||||

|

Net Weight |

550KG |

|

||||||||||

|

Gross Weight |

600 KG |

|

||||||||||

|

Machine Size |

1400x680x1200 |

|

||||||||||

|

Packing Size |

2.64 m2 |

|

||||||||||

|

Packing box |

|

|

||||||||||

Specification for semi-automatic strap seal machine

|

NO |

Items |

Data |

|

1 |

Machining strip width range (mm) |

30~55 |

|

2 |

Machining strip thickness range (mm) |

0.3~0.9 |

|

3 |

Seal inner width range (mm) |

10~100 |

|

4 |

Steel material |

Zinc coated steel coil |

|

5 |

Feeding range (mm) |

380 |

|

6 |

Main motor power (kw) |

1.1 |

|

7 |

Seal inner width(mm) |

16,19,25,32,40 |

|

8 |

L*W*H(mm) |

1100*700*1200 |

|

9 |

Weight(kg) |

300 |

|

10 |

Model |

FR-5 |

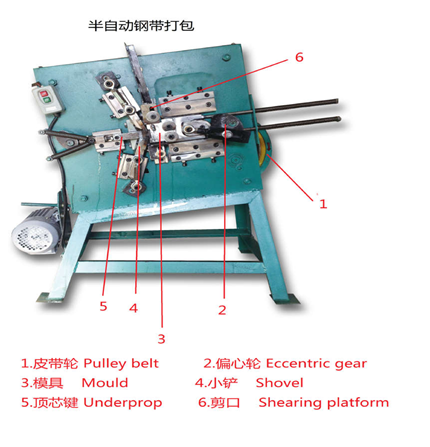

- Connect the power supply, make sure the running direction of the belt pulley(1) same as the arrow direction on the pulley.

- Turn off the machine, run the machine by hand through pulley. Make the Mould(3) to the top place.

- Feed the raw material into the machine through the shearing platform(6)

- Do not turn on the machine! Produce 3-5 seals manuelly through the belt puley. Make sure every seal can be pushed out.

- Then turn on the machine to produce the seals.