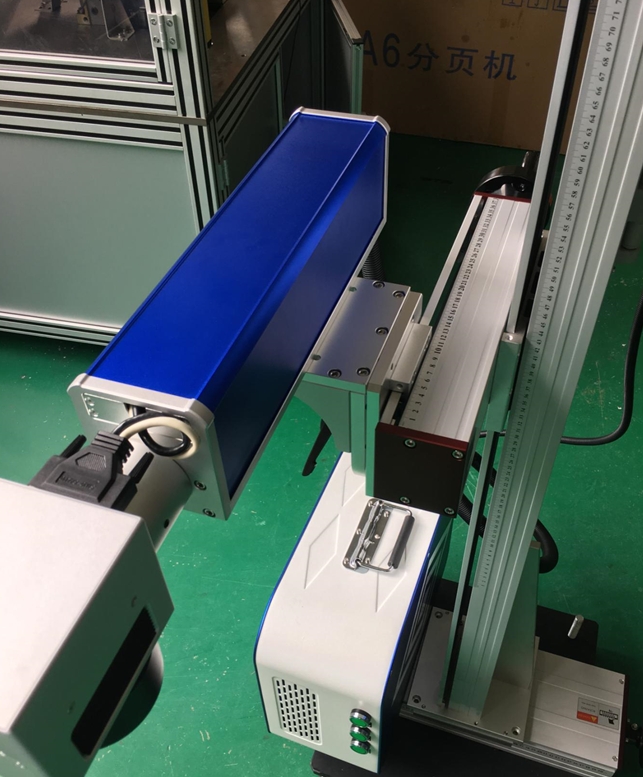

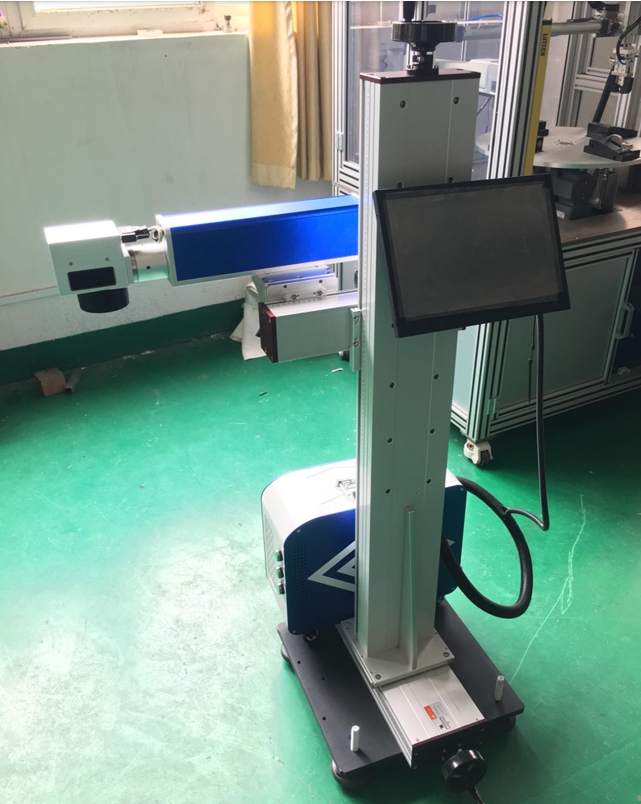

Laser printer for steel pipe online printing in production line

(1). Delivery inspection related issues:

1. Delivery cycle: 3 days (depending on the actual delivery situation)

2. Delivery method: logistics delivery

3. Training time: 1-2 days

4. Inspection qualification method: meet customer product demand and functional requirements

5. Whole machine warranty period: 24 months

6. Pipeline coding: between the pipe delivery equipment and the pipeline traction equipment, the coding section pipeline is positioned, coded, and metered by the meter wheel designed by the frame, and the software is improved on the basis of the original equidistant laser coding to achieve 3 (or more) intervals of cyclic coding in the pipeline.

(2) 30W fiber optic machine configuration:

|

Project |

Specifications |

Brands |

Notes |

|

Laser |

30W fiber laser |

Raycus |

Best domestic brand, German imported module |

|

Galvanometer |

≤12000mm/s |

Golden Haichuang |

High-speed servo precision, adjustable speed, imported laser head |

|

Field lens |

100mm*100mm |

Singapore Wavelength |

Optional range |

|

Marking card |

Marking card |

Golden Orange |

Lifetime free upgrade |

|

Laser power supply |

24V 350W |

Taiwan Mean Well |

Long life |

(3)Performance parameters:

|

Laser power |

30W |

|

Laser repetition frequency |

1.2KHz—25KHz |

|

Laser wavelength |

1064nm |

|

Marking range |

100×100mm (optional) |

|

Minimum line width |

0.1mm |

|

Minimum character |

0.4mm |

|

Maximum marking speed |

12000mm/s |

|

Maximum marking depth |

3mm (depending on the test material) |

|

Repeat accuracy |

±0.01mm |

|

Maximum assembly line speed |

70m/min |

|

Maximum number of flight marking lines |

3rows |

|

Character type |

Chinese/English character, number |

|

Power requirement |

220∨ (±10%)/50Hz/15A |

|

Total power |

300W |

|

Cooling method |

Wind cooling |

|

Total weight |

65KG |

(4) Performance characteristics:

* High-speed scanning galvanometer, stable light output.

* Clear marking, not easy to wear.

* The engraved graphics are clear and beautiful, and the performance is stable.

* The system can automatically encode, automatically print serial numbers, batch numbers, dates, etc.

* The laser galvanometer has high scanning accuracy, fast speed and stable performance.

* High marking accuracy, fast speed, and arbitrary control of engraving depth.

* The software control system uses WINDOWS XP as the operating platform, with a full Chinese interface, and is compatible with a variety of file outputs such as AUTOCAD, CORELDRAW, and PHOTPSHOP.

(5). After-sales service commitment:

1. Two-year warranty for the whole machine and lifetime maintenance;

2. Free installation, debugging and training for operators and maintenance personnel;

3. Free software upgrade;

(6) Acceptance method:

1. Acceptance at the equipment use site;

2. Acceptance of completeness (data, spare parts) and product appearance;

3. The supplier sends personnel to install and debug the equipment;

4. Demonstration of various functions of the equipment;

5. Ensure that the machine is adapted to the processing technology of the buyer;

6. The supplier marks the workpiece selected by the buyer and checks whether the marking meets the requirements;

7. Test relevant technical indicators;

8. The supplier sends personnel to conduct technical training for the buyer's operation and maintenance personnel for 2 working days;

9. After the equipment is debugged without any faults, representatives of both the supplier and the buyer sign the acceptance report.

(7) Training

1. The supplier sends personnel to the buyer for on-site training (implemented after the equipment is installed and debugged).

2. Training personnel: operators, electrical and mechanical maintenance personnel, the number of which is determined by the buyer.

3. Training content: Equipment installation and debugging and marking machine principles, composition and common computer knowledge. Computer programming, electrical control principles and daily equipment maintenance, etc., and actual operation. Equipment common troubleshooting training, further familiarity with the equipment, answering questions, and finally assessing the trainees.

(8) Quality Assurance Service

1. The supplier provides the following technical support to guide the purchaser to use and maintain the equipment safely and correctly.

(1) Instructions for use of the equipment and backup of application software;

(2) Product certificate.

2. The warranty period is 24 months, starting from the date of signing of the final acceptance result. Repairs are free of charge during the warranty period, and repair fees will be charged at the discretion of the purchaser outside the warranty period.